-01-cropped%20(1).svg)

%20(3).png)

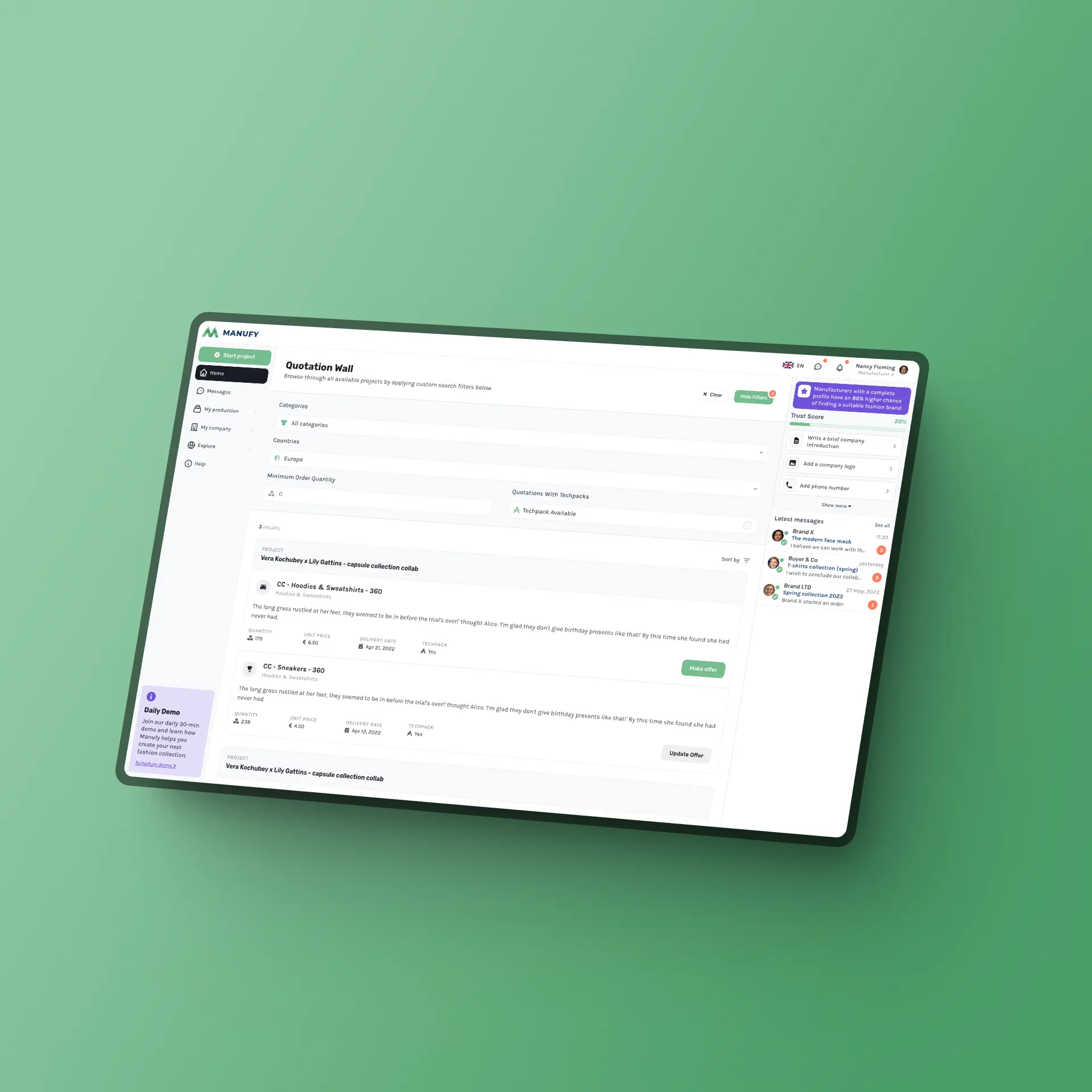

Το Manufy είναι μια λύση 360 μοιρών με γνώμονα τα μέλη για τη σύνδεση επωνυμιών, προμηθευτών και άλλων παρόχων στην Ευρώπη. Προσφέρουμε απλές συμβουλευτικές υπηρεσίες αντιστοίχισης, σε 1 προς 1, ανάλογα με τα σημεία πόνου για τα οποία χρειάζεστε βοήθεια εντός της επωνυμίας σας.

Η πλατφόρμα Manufy προσφέρει μια ολοκληρωμένη λύση, απλοποιώντας τη διαδικασία παραγωγής σας από την αρχή μέχρι το τέλος, εκσυγχρονίζοντας το βιώσιμο ταξίδι σας στη μόδα.

Προβάλετε τις βιώσιμες πρακτικές παραγωγής σας και συνεργαστείτε με επωνυμίες στην πλατφόρμα Manufy - την πρώτη πλατφόρμα βιώσιμης προμήθειας B2B στην Ευρώπη!